Meet our Expert

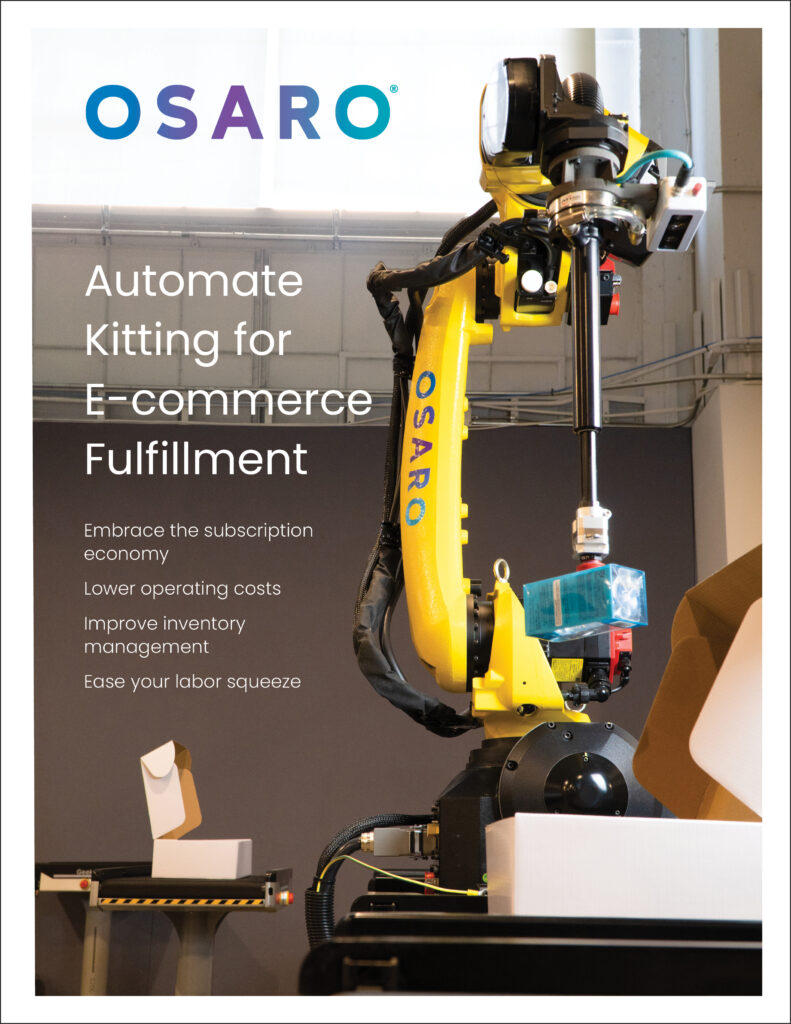

Tracy Perdue has 20 years of industry experience working with Dematic, Intelligrated, and Conveyco Technologies, among others. Much of his work has been focused on getting automation right for regional and national 3PLs distributing products for a variety of retailers. Perdue’s self-described approach is ‘Let’s get real.’ He aims to find the right answer to meet a specific situation, not a one-size-fits-all solution. Perdue is Vice President of Solutions and Sales at OSARO, an AI-driven robotics company that provides piece-picking solutions for e-commerce.

Learn more about the benefits of robotic kitting in warehouse automation.

Explore our other Ask an Expert blog topics about robotic bagging, robotic depal, and more.

Why 3PLs need to automate kitting

By OSARO Staff | Ask an Expert series

Like other forms of automation moving rapidly into distribution centers, robotic kitting can help third party logistics (3PL) providers meet the surge in demand for increasingly popular, curated subscription orders. Indeed, revenues from e-commerce subscription products are projected to grow 25 percent annually from 2020 to $687 billion in 2025, according to UBS Financial Services.* For fulfillment operators, automated kitting streamlines a labor-intensive, error-prone manual process and achieves greater efficiency.

Meanwhile, investment in warehouse automation is expected to continue rising in 2024, despite a last year’s post-pandemic slump. With that in mind, 3PLs won’t want to be left behind. Instead, they need to be ready with automation for kitting and other functions as e-commerce continues to grow. OSARO expert Tracy Perdue explains.

Is this the right time for 3PLs to invest in robotic kitting?

Perdue: Yes. In fact, you really can’t afford not to with e-commerce continuing to expand. It was forecasted to grow 56 percent from 2021 to $8.1 trillion in 2026, according to Statista. The 2022 slowdown in new warehouse construction is now easing and automation research firm Interact Analysis projects revenue growth rates for warehouse automation will approach 20 percent resulting in a $60 billion market by 2027. While much of that may represent warehouse capacity expansion by distribution giants like Amazon, Walmart, and Target, 3PLs need to be ready with equipment that can relieve the pressure for more processing demand from smaller regional retailers as e-commerce continues to expand across the board.

Moreover, robot-as-a-service (RaaS) contracts now make the investment in new systems less expensive and less risky by shifting the cost from capital expenditure to annual operating budgets. And that makes it easier to make the business case to your C-suite.

What advantages does automated kitting offer 3PLs?

Perdue: I’ve worked with 3PLs for decades. They need to respond to their retailers (who are often in a pinch) with speed – and with accuracy. In today’s competitive market, there is no room for delays or botched shipments. For 3PLs, robotic kitting creates four advantages:

Improved picking accuracy

Kitting typically involves picking, placing, and packaging a collection of curated products such as weekly meal kits or monthly boxes of pet products. Kitting in 3PLs has traditionally been handled by humans putting items or parts in boxes along tables or a conveyor, or at a workstation. The jobs are repetitive, boring, and prone to error. Using smarter, AI-driven robots means fewer mistakes. That leads to reduced returns, less repeated work, faster processing, and happy customers – at both the 3PL-client (retailer) and end-user levels.

Scalability

Robotic kitting supports higher throughput. Robots can work 24/7 without breaks during seasonal surges. They can be turned off or made to work overtime at a moment’s notice without retraining or trying to hire in the excruciatingly tight labor market.

Flexibility

Robotic kitting lines provide 3PLs with flexibility since they can be moved around the warehouse as needed and are not bolted to the floor. Warehouse space permitting, robotic systems can be expanded with additional robots.

Improved inventory control and predictability

The repeated purchase of kitted subscription products makes it easier for 3PLs to predict their revenues from fulfillment services. The ability to pre-assemble boxes reduces surplus inventory and allows better planning for surge periods. Data available from robotics and warehouse management systems can also improve the forecasting of surges or item shortages.

What should a 3PL look for in a robotic kitting system?

Perdue: Consider five key factors when assessing robotics for kitting:

1. How precise is the robot’s machine learning vision? Is the robot’s 3D vision and machine learning software and control system able to pick up uniquely shaped items carefully and with precision, especially if delicate items such as foodstuffs or cosmetics are involved? How many SKUs can it handle? How long does training the robot on each new product mix for the kitting line take?

2. Is there a tool-changing bar? Does the robot have the ability to deal with items of different textures, such as a fluffy toy versus a package of snacks? Can it access a toolbar with different end-of-arm tooling (EOAT) devices, ranging from finger-like grippers to suction cups of different sizes and compressed air strengths.

3. Does it meet your operational requirements? Can it handle the required throughput for your kitting clients? What is the robot’s cycle time? Is there adequate floorspace? What does your vendor estimate downtime for maintenance and replenishment will be?

4. How will it integrate? What will it take to integrate the system with your existing conveyors, AMR/ASRS system, and warehouse management system (WMS)? Will the robotics fit within your overall warehouse workflow?

5. How does the vendor define support and maintenance? What technical support and maintenance service is your vendor offering? Is there onsite deployment support? For how long? Will your staff be properly trained to manage and oversee the robots?

*UBS Financial Services research report. Investing in Digital Subscriptions, March 2021, UBS Chief Investment Office, Sundeep Gantori, Delwin Kurnia Limas, Kevin Dennean