Zenni Use Case

Robotics Drives Productivity and Accuracy at Zenni

Video: The Zenni Robotics Experience

Use Case Summary

After years of searching for a robotic solution to process millions of pairs of eyeglasses annually, Zenni Optical chose OSARO to automate its fulfillment. Zenni’s objective was not just improving speed and lowering cost but ensuring accuracy and a quality customer experience. Building loyalty and trust in its prescription eyewear is critical to the company's brand promise.

Following a deep-dive assessment of Zenni's multi-step handling process, OSARO completed a robotic deployment that delivered an 80% increase in productivity – and created a process with 99.9% accuracy.

Today, each OSARO® Robotic Bagging System at Zenni is capable of processing up to 410 eyeglasses an hour using fewer handlers, which gives the company flexibility to redeploy people to other tasks that still require human intervention. At the same time, employees were upskilled, giving them less tedious work and new opportunities.

The Company

One of the Big 4 online eyeglass retailers, Zenni sells 6.5 million pairs annually – 6 million of them in the U.S. market alone. It packages and ships about 3 million from Novato, CA, and another 3 million from its Ohio facility. Now in its 20th year, the first online-only eyewear retailer has surpassed 50 million pairs of glasses sold, and has doubled sales in just the last four years. “We offer quality eyewear at an affordable price,” says Simon Goh, Zenni’s Director of Distribution and Facilities.

The Challenge

For years, workers manually placed each pair of glasses into clamshell cases, and then inserted the cases into a tabletop mechanical bagging machine, which spit them out in a labeled poly bag for shipping. The process was mind-numbingly tedious, slow, and prone to error. If just one item scanned out of sync with the product, it could result in unhappy customers squinting through incorrect lenses, returns, costly replacement product, and a loss of invaluable customer trust.

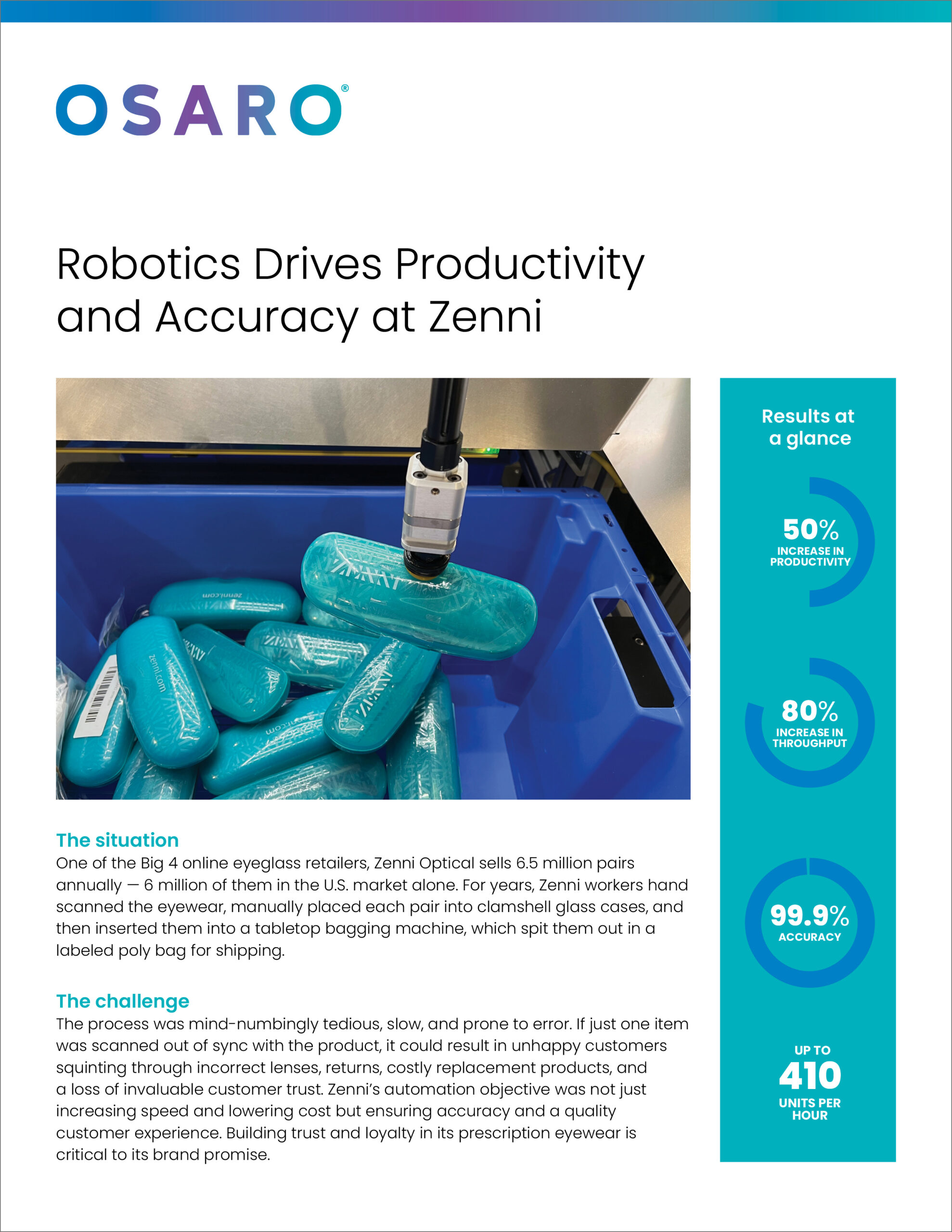

Results

At a glance

50% increase in productivity

99.9% accuracy

80% increase in throughput

Up to 410 units an hour

The Solution

OSARO’s AI-driven SightWorks™ vision and control software delivered the robotic intelligence needed to identify, precisely pick, and place the eyewear into an integrated bagging machine for shipping.

OSARO's solution also drew on carefully selected vendors it brought to the project, such as Pregis, which has 50+ years of experience in packaging. “We’ve developed the OSARO Partners Alliance, which is an ecosystem of the best technologies that we have found in the industry,” said VP of Operations Gemma Ross.

The key components of the OSARO® Robotic Bagging System are a FANUC M-10 Series robot arm powered by SightWorks™, a Pregis Sharp™ automated bagging machine, Cognex DataMan scanners, Framos cameras to guide the robot, and Smart Vision lighting. NPSG Global constructed the physical infrastructure with OSARO’s technical team.

The Results

Following its deep-dive assessment of Zenni's multi-step process, OSARO completed a deployment that delivered an 80% increase in throughput. Zenni estimates that 2 people working with the robots could do the work that previously required 3 people – and more accurately. By moving to robotics, Zenni was able to achieve 99.9% accuracy by reducing most of the risks inherent in manual processing and eliminating errors which could sometimes range anywhere from 5 to 30 a month.

Today, each OSARO robotic system is able to pick, scan, bag, and label up to 410 eyeglasses an hour. The average can hover closer to 350 an hour when downtime to replenish bags or maintain the system is considered, but the system's machine learning is also expected to continuously improve performance over time. With seasonal surges sometimes creating the need to process up to 450,000 units in a single month, robots provide valuable flexibility. They can work longer than humans, allowing the company to redeploy people to other tasks that still require human intervention, such as unpacking boxes or processing returns.

At the same time, employees were upskilled, giving them less tedious work and new opportunities.

End-to-End Support

Technology is just one part of OSARO’s engagement. Considering the automation journey from start to finish, Goh said he couldn’t have done it without OSARO's constant guidance and intervention, a process OSARO calls Hypercare. “Our Hypercare customer support program was purposefully designed to tackle the inevitable complexities of implementing new fulfillment processes,” said Ross.

OSARO leveraged its partner vendors to solve challenges particular to Zenni. The eyewear maker’s signature glass cases stymied several scanner-makers that were unable to read barcodes through the translucent blue plastic case. OSARO sought and vetted a number of suppliers before landing on the Cognex product that was able to do the job and was easy to use in the field.

Similarly, OSARO’s deployment support team worked with vendors to troubleshoot other problems. For example, printer lines or wrinkles in the shipping labels sometimes made it impossible for postal services to track the item during shipping – a reassurance customers have come to expect as they are notified of their purchases in transit. OSARO worked with Pregis to install a barcode verifier so that an alert would signal any time a printed label was not trackable. The item could be identified and properly reprocessed.

“We went through all the issues we needed to deal with every week. We worked together with OSARO more like a partner, trying to address each issue. When it comes to the project management team from OSARO, we had a very good working relationship,” ~Simon Goh, Zenni Director of Distribution & Facilties

Download the Case Study

Hypercare

OSARO's Customer Support Program

1. Scoping and planning

2. Installation

3. Acceptance

OSARO’s five-phase program includes Scoping, Installation, Acceptance, Deployment, and Performance Monitoring. On-site technical staff execute the deployment over several months and a senior customer success team member manages the deployment in weekly meetings with Zenni.

OSARO’s Hypercare support process includes:

- Scoping: The process starts with listening to the customer to establish detailed needs and pain points. This yields a thorough understanding of how the automation can fit into an existing operation.

- Installation: OSARO leverages partners to assemble the precise expertise needed to meet each client’s specific use case.

- Acceptance: The team conducts rigorous system testing and holds weekly meetings to ensure client expectations while managing vendors and troubleshooting issues as they arise.

- Deployment: OSARO co-develops comprehensive Standard Operating Procedures with the customer, performs operator training, and incorporates Voice of Customer feedback for system fine tuning and final polish.

- Performance Monitoring: OSARO kicks off remote monitoring of system performance and regular executive business reviews to ensure continuous customer success and optimal system performance.

"Before we engaged with OSARO, we thought of doing some kind of robotic automation ourselves,” said Goh. “Looking back, I can’t imagine we would have even considered doing that. We have to integrate so many different pieces of equipment; it's just impossible to do without a professional company like OSARO." ~ Simon Goh, Zenni Director of Distribution & Facilties

Key Takeaways

Robotics reduces errors, allows workers to be more effective, and provides more operational flexibility.

Be sure the technology is the right fit for your needs and is designed to fit into your day-to-day operation.

Work with a vendor who provides full on-site engagement and support through deployment.

Ensure your team is trained by the vendor to operate and maintain the robotic system independently.

Robots and People: Leveling the Playing Field

When robots entered the warehouse, Zenni Optical's automation champion Simon Goh made a stunning discovery about worker productivity. The robots made his workers more productive – way more productive.

Goh knew that people worked at varying levels but he didn’t realize what a difference robotics could make in the fulfillment process. In one audit comparing worker output on a manual station versus working with a robot over five-day periods, he discovered that the robots made his slowest workers up to 70% more productive. And even his fastest manual processors’ performance shot up 20%. The metrics Goh collected over several months varied, but the upward trajectory was consistent.

“With robots we have leveled the playing field for our employees, he said. “Now their performance is more even. It reduces mistakes and increases productivity.” ~ Simon Goh, Zenni Director of Distribution and Facilities.

The increase was due not only to fast, consistent throughput by the robot. By employing robotics, the company was able to cut the number of steps needed to process a pair of eyeglasses for shipping from five steps to two steps, making everyone more productive. Moreover, it took fewer people to process the products so employees could be assigned to other more interesting tasks that still require human intervention.

Workers seem to like it, too. Their work is streamlined, more varied, and they have acquired new skills. “Managing the robot is easier and better than stuffing packages,” said Minjie Hu, who completed training as a robot operator. “Learning new skills is better.” Adds Shipping Supervisor Blyn Prokopowich, who oversees the processors, “Robots have removed tedious tasks and enable us to deploy our team to do other projects like returns and multiple orders.”

Contrary to media hand wringing about robots taking people’s jobs, Goh says Zenni has absolutely no plans to lay off anyone. “Automation is going to help retain jobs in the U.S.,” he said. “The US has higher labor costs, but with robots you can reduce the difference between the U.S. and developing countries."

Our Zenni Project Partners

An eco-system of expertise

Advantages of Robotic Automation

Smart robots are making a difference across the warehouse from bagging and kitting to depalletizing and piece-picking for AMR-ASRS systems.

Smart picking

Identifies, picks, and packs subscription kit items into boxes.

Accurate placement

Accurately places items into a curated box to ensure proper packing fit.

Adaptable

Adapts to changing inventory and new monthly items on the fly. No previous registration required.

Flexible

Easily repurposed to work with different conveyors or AMR/ASRS systems as needs change in the warehouse.

Low Risk

Robot-as-a-Service (RaaS) plans operationalize costs and to lower risk and avoid costly capital expenditure.