Use Cases

Powering the supply chain

OSARO's machine learning empowers industrial robots to meet the demands of today's e-commerce fulfillment centers. OSARO works directly with warehouse and material handling technology providers from Singapore to Tokyo and in cities across the U.S.

Geek+ AMR/ASRS Integration

OSARO has integrated its pick-and-place robots with Geek+ AMR/ASRS warehouse automation systems, offering a one-stop solution for warehouse fulfillment operations. The interoperability of OSARO-powered robots with warehouse systems is made possible by its latest REST API, which offers greater flexibility in what the systems can be asked to do.

Robotic Bagging at Zenni Optical

At eyeglass e-tailer Zenni Optical's distribution center in California, OSARO® Robotic Bagging Systems are in production deployment to pick, place, and polybag some of the thousands of eyeglasses Zenni sells online to the U.S. market each year. Robots have enabled a 50% increase in productivity.

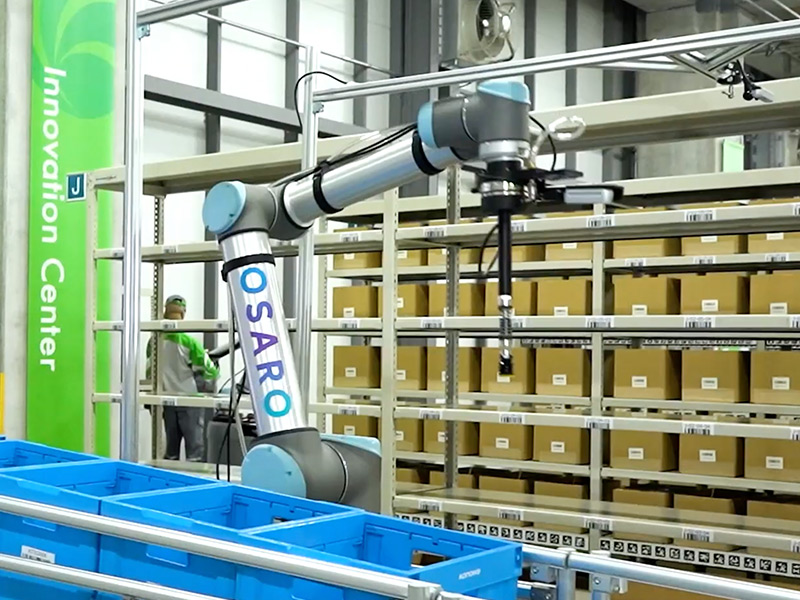

Automated warehouse with Konoike Transport

OSARO teamed with Konoike Transport to develop the first automated warehouse in Japan. An InVia AMR retrieves items from a shelf and brings it to an OSARO pick-and-place robot station. The robot then picks items from the bin and places them in different bins on a conveyor for shipment downstream.

Bin Picking at SVT Robotics

OSARO’s machine learning pick-and-place robot is available for customers to view at SVT Robotics’ Innovation Lab in Norfolk, VA. Together, SVT, with its SOFTBOT integration platform, and OSARO are able to optimize every stage of a customer’s integration and deployment process.