Meet our Expert

Ryan Tanaka is an industrial automation expert who joined machine learning-enabled robotics maker OSARO in 2020 just as e-commerce fulfillment growth exploded and new generation of AI-driven robots became available to take on expanded automation tasks. He has worked with integrators, 3PLs, and retail companies. As senior sales associate, Ryan prides himself on helping customers understand upfront how robotic solutions can potentially meet their particular processing needs. From the Midwest, Tanaka, who is bilingual, also worked several years in Japan. He previously worked at NTC America as a sales engineer. Prior to that he was in operations and CRM systems at Tecdia, a Japanese electronic components manufacturer. Tanaka is a graduate of Michigan State University and has an executive program certificate in Supply Chain Management.

Solve labor and demand challenges with robots

By Barbara Buell, OSARO Ask an Expert series

High demand, a persistent labor shortage, and consumer expectations for faster delivery and lower prices have made smarter warehouse automation essential to the future of e-commerce. One way to address all these pressures at once is with robotic bagging systems. OSARO industry expert Ryan Tanaka explains.

What is the role of robotics in warehouse automation?

Tanaka: Although e-commerce fulfillment centers are already populated by miles of conveyors, mobile robots (AMRs), and automated storage and retrieval systems (ASRS), a new generation of intelligent, piece-picking robots can perform automated bagging, kitting, depalletizing, decanting and sorting – tasks until now performed by manual operators. In the automation industry, we call this a shift from the Goods-to-Person (GTP) function to the Goods-to-Robot (GTR) segment of warehouse technology.

What is driving the need for robotic bagging?

Tanaka: There are four elements: increasingly competitive pricing, the labor shortage, injuries, and seasonal spikes. Utilizing robots in new GTR roles is a crucial area where the greatest remaining gains in efficiency can be achieved. Robots can meet or exceed manual labor throughput, can ramp up easily during seasonal crushes when labor is hard to find, and can work 24/7 when needed. Smarter robots will also create new and more stimulating jobs for people within the warehouse while avoiding tasks that can lead to injury. Bagging, in particular, is complex and has been left to manual operators – until recently.

What is a robotic system?

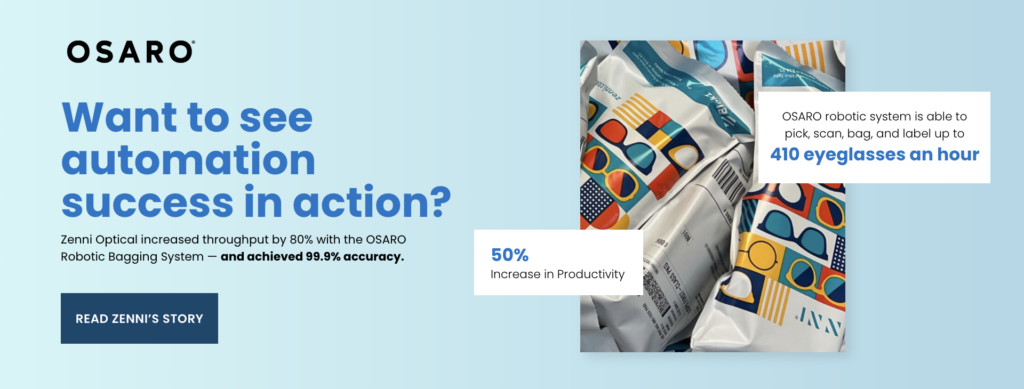

Tanaka: Smart pick-and-place robot arms using advanced perception-and-control software are now integrated with traditional mechanical bagging machines to automate the entire order fulfillment process. Robots replace manual operators by picking and scanning items one by one before placing them directly into a mechanical bagging machine. The first of these end-to-end systems, the OSARO Robotic Bagging System introduced in 2022, pairs a FANUC robot arm powered by OSARO’s machine learning software with poly bagging machines from trusted vendors. It is capable of packing and shipping a wide range of typical e-commerce SKUs on a 24-7 basis with minimal human oversight.

What is the scope of the labor problem in warehouses?

Tanaka: The labor shortage is a persistent problem that is not going away based on demographic trends. Baby boomers are retiring and population growth rates are not keeping up enough to replace them. In February, the U.S. Labor Department reported a 3.4 percent unemployment rate, the lowest in 53 years, while employers added 517,000 new jobs.

A 2022 report by the Material Handling Institute (MHI) found that hiring and retaining workers was the second largest challenge identified by 1,000+ supply chain leaders it surveyed – a problem second only to supply chain disruptions and shortages.

In addition, seasonal spikes created by holidays and/or supply chain disruptions create havoc with labor hiring and scheduling. Online retail is more logistically rigorous per-unit, compared to storefront retail. Not only is it extremely difficult to scale up hourly workforce levels but adding more manual labor increases costs and inefficiencies.

How does a robotic bagging system work?

Tanaka: Until now, a typical poly bag packaging station consisted of an automatic mechanical bagging machine and an operator. Today’s full robotic bagging process can be broken down into these steps:

~ First, items are retrieved from warehouse inventory shelves, preliminarily sorted into totes or bins, and transported to the product bagging station by an automated storage and retrieval system or an autonomous mobile robot.

~ Second, the robot picks an item up, enabled by machine learning software to understand how to grasp different shapes and textures.

~ Next, if needed, the robot moves each item to a barcode scanner for identification. A shipping label is printed and applied to the bag.

~ Then, the robot places the item into an open bag within the mechanical bagging machine.

~ Finally, the bagging machine seals the bag and discharges it onto a conveyor for downstream shipping.

In addition to reducing packaging and shipping costs with poly bags that are lighter weight and density than boxes, robotic bagging systems increase throughput (by opening, closing, and sealing bags more quickly than an operator can). They also reduce packaging errors due to improper closure. Further savings are realized because the manual bagging and packaging process is cumbersome and requires training. By streamlining the process you are also able to reduce your carbon footprint.

How do you make the business case for a robotic bagging system?

Tanaka: The good news is that making the business case for investing in automation has gotten easier. Most automation vendors are moving toward Robot-as-a-Service (RaaS) contracts, which shift expenses from large, risky capital expenditures to controlled operational costs that can be adjusted as needs change. And with interest rates up, RaaS contracts remove another barrier to investment in automation. Access to cheaper cloud computing and storage needed for AI driven robots has also changed the cost equation for robotics. For retailers with distribution centers, warehouses, and third-party-logistics operations, investing in robotics for e-commerce fulfillment is no less than a strategic imperative.

Those e-commerce organizations that can solve the operational challenges presented by new forms of ordering and delivery will be well-positioned to meet a very competitive marketplace. Their success will depend on highly efficient fulfillment engines capable of rapidly and cost-effectively delivering tens of thousands of SKUs to customers.

What questions should I ask a vendor if I consider robotic bagging?

Tanaka: First it is important to identify what problem you are trying to solve. A good vendor will help you with this. Will the vendor perform an upfront feasibility study with you to make sure you are getting the right solution to the problem you have identified?

Will they offer a detailed plan for deployment and follow-up support? How will the vendor’s system integrate with the existing Warehouse Management System? Robotic systems are complex and require a sustainable operations plan. Furthermore, is maintenance included in your RaaS contract?

Finally, the people who currently manage your warehouse floor are important. How will you integrate them into planning and train operators to work with your robots? Upskilling is a great way to retain employees and reduce retraining costs.