OSARO and Zenni Deploy Industry’s First Robotic Bagging System in Demanding, Precise Production Environment

Three robotic bagging systems to be deployed at Zenni’s Northern California customer fulfillment center; job description calls for visual acuity, precision, dexterity — and tireless work ethic

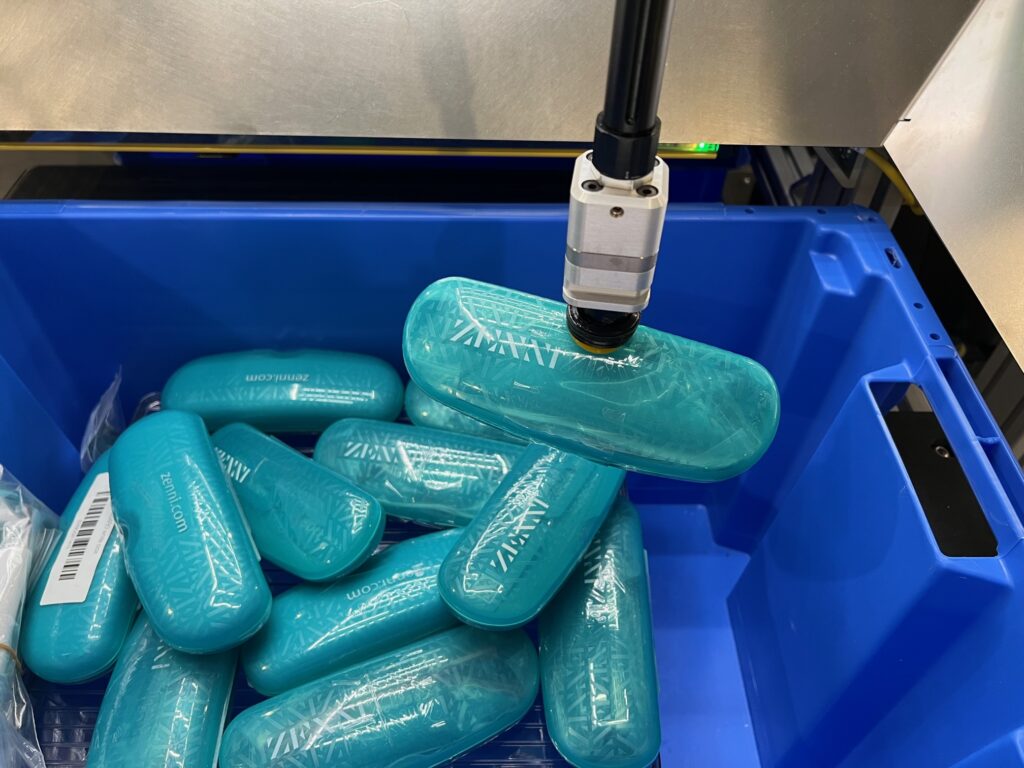

SAN FRANCISCO – June 22, 2022: OSARO™, a global leader in the development and deployment of advanced robotics for e-commerce, has partnered with Zenni®, the online eyewear retail leader, to automate the ‘last meter’ of Zenni’s fulfillment center in Novato, California. Three OSARO™ Robotic Bagging Systems will take on the responsibility of readying eyewear orders for shipment to U.S. customers.

The deployment is also an industry first. This is the first time a robot will be assigned the responsibility of working with an automated mechanical bagging system to ensure a customer’s unique order is placed into the correct bag for shipment. OSARO has partnered with Pregis, a trusted supplier of automated bagging equipment, to meet Zenni’s needs. OSARO’s superior vision and grasping technology enables the robot to rise to the challenge of this particular piece-picking task, which is of importance to Zenni since each eyeglass order is associated with a customer’s prescription.

“We are focused on quality and innovation. With a mountain of online orders and a persistent shortage of labor, we looked to OSARO to take us to the leading edge of technology to be sure our customers receive fast and accurate processing.”

— Simon Goh, director of distribution and facilities at Zenni

“We are focused on quality and innovation,” said Simon Goh, director of distribution and facilities at Zenni, which has surpassed 45 million pairs of eyeglasses sold over 19 years of growth. “With a mountain of online orders and a persistent shortage of labor, we looked to OSARO to take us to the leading edge of technology to be sure our customers receive fast and accurate processing.”

“The stakes are high here: special-order, high-value items that must be bagged and labeled correctly to ensure they are sent to the right customer,” said Derik Pridmore, CEO of OSARO. “Our extensive experience in other e-commerce production environments, coupled with our machine-learning capabilities, enables our robotic bagging system to meet customer production targets and to deploy workers onto more important tasks.”

The project will optimize the use of a pick-and-place robot to perform a complex task that demands visual acuity, precision, and dexterity. Zenni has a team of workers capable of handling 10 orders per minute and accuracy is key to making sure that the right order gets to the right customer. Deploying robots to handle e-commerce processing also mitigates labor turnover and staff shortages that are challenges in the rapidly growing e-commerce fulfillment sector.

About Zenni

Zenni® pioneered the online eyewear industry in 2003 with a mission to make prescription eyewear affordable and accessible to everyone. Based in the San Francisco Bay Area, Zenni offers men, women, and children the freedom to express their personal style through high-quality prescription and protective eyewear curated with a sense for fashion and incredible selection. With complete prescription pairs starting at just $6.95, and averaging just over $40, the company has brought massive price disruption to the traditional retail model. With over 45 million frames sold worldwide, a pair of Zennis is owned in every country across the globe. Zenni is proud to be the exclusive eyewear partner of Iris Apfel, as well as the Official Eyewear of the San Francisco 49ers, Boston Red Sox, Call of Duty League, and the Chicago Bulls. Zenni also partners with actor and producer Rashida Jones and fashion designer Cynthia Rowley. For more information, please visit zenni.com.

About OSARO

OSARO delivers best-in-class robotic piece-picking solutions for e-commerce where key challenges include high SKU inventories, complex packaging, and fragile items. In the rapidly evolving world of logistics technology, OSARO offers smarter automation, low-risk business plans, and its signature Hypercare support from exploration to installation. OSARO’s intelligent robots enable goods-to-robot (G2R) use cases, where the greatest gains are yet to be made on the automated warehouse floor. Its machine-learning vision and control software provides the foundation for all its products. For more information, visit osaro.com.

The names of the companies and products/services mentioned in this news release are the registered trademarks or trademarks of their respective owners.

Media contact: Tim Cox, ZingPR, tim@zingpr.com