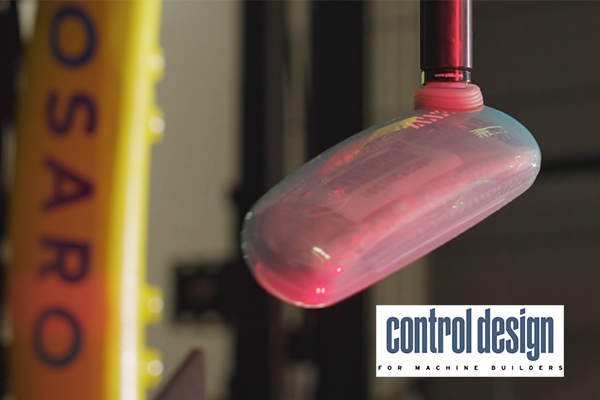

OSARO’s AI-powered order-fulfillment robots adapt to new products in real time

This marks a significant advancement in its OSARO SightWorks™ perception platform. In order fulfillment, where speed is critical, businesses often face days or even weeks of costly downtime to update their robots for new SKUs.