By Brent Barcey, SVP of corporate development

As SVP of corporate development, Brent Barcey brings 25 years of experience growing global businesses and teams in the e-commerce, warehousing, and logistics industries to OSARO, where he will spearhead the company’s commercial growth as it addresses the surging global demand for e-commerce fulfillment solutions.

In today’s fast-paced e-commerce world, speed and adaptability are essential. As the holiday season approaches, warehouses and distribution centers are under pressure to keep up with evolving customer demands, new SKUs, workflow changes, and seasonal staff. Traditional fulfillment robots, with their fixed programming and limited adaptability, often face challenges meeting these needs.

What causes this problem?

Most warehouse robots rely on pre-programmed routines and computer vision models fine-tuned to specific items they’ve been trained on. When dozens of new SKUs enter the line, each with distinct shapes, sizes, and material properties, these robots require manual reprogramming to handle the variations effectively. This retraining process can take days, if not weeks, resulting in lost productivity and costly order delays.

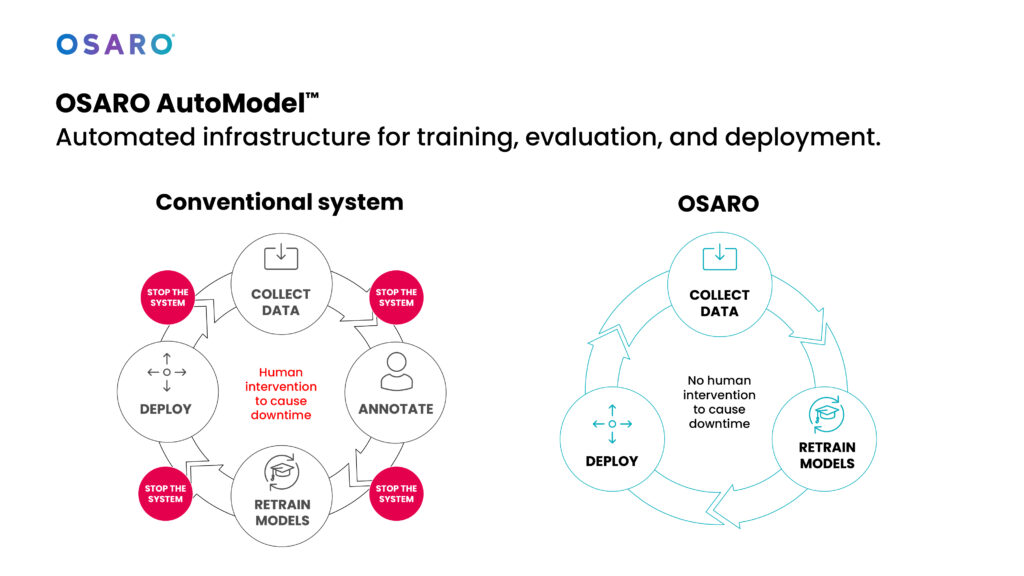

To address this, OSARO has introduced OSARO AutoModel™.

OSARO AutoModel: Real-time learning, no human intervention needed

This AI-powered software enhancement to OSARO SightWorks™ enables robots to recognize new SKUs and adapt to handling them autonomously. AutoModel facilitates an unprecedented level of flexibility, supporting more responsive and efficient workflows as businesses introduce dozens or even hundreds of new items.

In this post, I’ll share insights into the development of AutoModel, explore its unique capabilities, and explain why it’s a valuable tool for businesses aiming to improve fulfillment efficiency.

The genesis of OSARO AutoModel

AutoModel’s development was driven by customer needs to accelerate SKU onboarding. Customers asked if OSARO could reduce the time required to integrate new products into their fulfillment systems. They wanted a process that minimized downtime and manual intervention.

“Our customers’ request for faster SKU onboarding made it clear that more adaptable, real-time solutions were needed,” explains Gemma Ross, VP of operations at OSARO. “We recognized that to support fast-paced fulfillment demands, a shift from traditional robot programming methods was essential.”

This challenge led OSARO’s team to rethink their approach. Kitt Miller, head of machine learning at OSARO, explains further:

“AutoModel was designed with two core goals: to reduce the manual effort and time required for new SKU training and to provide customers with the flexibility to adjust their operations independently, without needing continuous support from OSARO.”

A change of perspective

AutoModel development was an iterative process. Shifting from a “detect-first” to a “grasp-first” framework, OSARO’s engineers aimed to enable robots to handle diverse items while maintaining precision and reliability. This shift allowed the system to operate with greater adaptability.

Practical benefits and impact of AutoModel

Kitt Miller notes, “The onboarding time for new SKUs happens in real time instead of days or weeks.”

According to Gemma Ross, “AutoModel handles challenging items with ease, and our customers are pleased with the efficiency gains.”

Looking ahead

AutoModel’s future looks promising. As Kitt explains, “We’re continually working to enhance data efficiency, making learning faster and more intuitive.”

OSARO AutoModel isn’t just a software update; it’s a paradigm shift in robotics. By applying machine learning to continually optimize robot perception skills, AutoModel represents OSARO’s commitment to innovation and excellence in fulfillment. For businesses looking to optimize their operations and maintain a competitive edge, OSARO AutoModel is the ideal solution.

Key benefits of OSARO AutoModel

- Fast deployment: Learns new SKUs quickly, minimizing training time and supporting a high return on investment.

- Maximum autonomy: Delivers high pick accuracy and efficiency with OSARO’s AI-driven perception algorithms.

- Zero disruption: Adapts to evolving SKUs, packaging, and workflows without costly retraining or downtime.

- Continuous improvement: Benefits from real-time AI model updates and consistent performance optimization.