Robotics for Automated Bagging

The OSARO® Robotic Bagging System

Automate item bagging by pairing OSARO's sophisticated pick-and-place solution with packaging equipment from leading automatic bagging partners for streamlined order fulfillment.

The system can package individual items at a rate of 350 parts per hour – equal to manual operation but with less overhead, no labor issues, and superior return on investment.

Benefits

√ Increase production without increasing headcount

√ Fit into your existing infrastructure and business

√ Completely automate order fulfillment

At a Glance:

Primary Use

Single item order fulfillment in e-commerce applications using poly bags.

Core Features

Pack and ship the majority of e-commerce items with limited manual labor.

Handle items without previous registration: Adapt to changing inventory and new items on the fly.

Scan barcodes quickly and efficiently to ensure orders are fulfilled and recorded correctly.

Relevant Industries

E-commerce, 3PL, factory

Cost Savings and Return on Investment

Up-front purchase or robot rental / Robot-as-a-Service (RaaS) options available.

Return on Investment (ROI): A five cell deployment will return, on average, 20-40% cost savings over five years when compared to an equivalent number of manual bagging stations (1-2 shifts per day and 24 operating days per month).

Supported Item Types:

Boxes

Dry Goods, Boxed Items, Cosmetics

Pouches / Envelopes

Prepared Foods

Bags

Loosely Packaged Items

Cylinders / Bottles

Liquids, Aerosols, Food

Tubes

Creams, Pastes

Blister Packs

Pills, Toys, Electronics

Multi-packs

Consumer Packaged Goods

Apparel (in bags)

Shirt in Polybag

We work with trusted partners

We work with trusted automated bagging machine manufacturers, integrators, and other vendors through the OSARO Partners Alliance to develop the best one-stop solution for our customers.

![]()

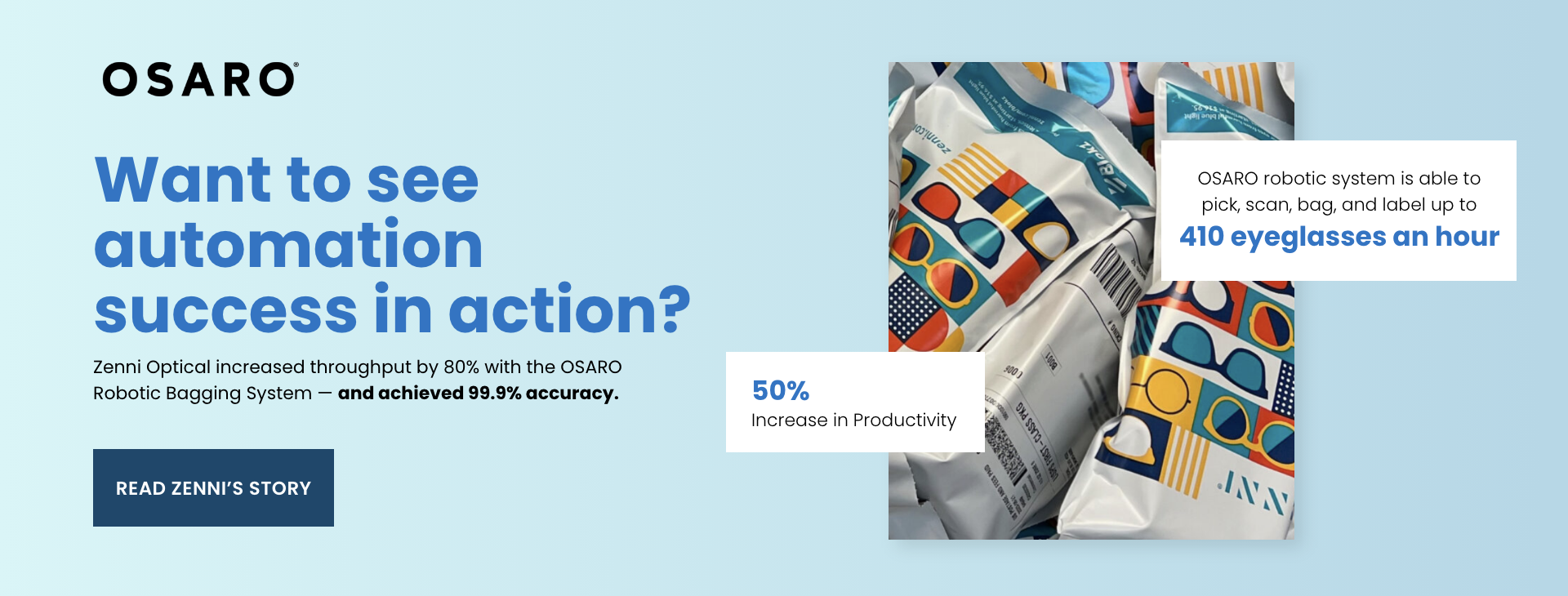

“We are focused on quality and innovation. With a mountain of online orders and a persistent shortage of labor, we looked to OSARO to take us to the leading edge of technology to be sure our customers receive fast and accurate processing.”

Simon Goh, director of distribution and facilities at Zenni

![]()

"PAC Machinery provides innovative packaging solutions that give our customers a competitive edge. By having PAC Machinery poly bagging systems fed by OSARO’s smart robots, it creates a new solution that will take customers to the next level of automation. This is the future."

Tom Zamiska, Product Line Manager, Rollbag Bagging Systems, PAC Machinery

"Pregis has always aspired to solve our customers’ toughest business challenges with packaging. We’re excited to showcase a new packaging innovation that combines our best-in-class automated poly bagging machines with OSARO’s leading pick-and-place robotics. This turnkey solution offers efficiency and automation that delivers enhanced levels of productivity.”

Eric Johnson, Director of Product Strategy, Pregis-Sharp

Automated Bagging Resources

Let's Talk Robotic Bagging!

Contact us to learn how OSARO's robotic bagging system can optimize your fulfilment operation.